3d Modeling in product design

WHY IS 3D MODELING USED IN PRODUCT DESIGN?

3d Modeling in product design

Introduction

Product design is vital in capturing consumer attention and driving sales in today’s competitive market.

Designers constantly strive to create innovative, functional, and visually appealing products that meet customer needs.

One tool that has revolutionized the field of product design is 3D Modeling.

By harnessing the power of three-dimensional virtual representations, 3D Modeling enables designers to bring their ideas to life and streamline product development.

This article will explore why 3D Modeling is extensively used in product design.

We will explore its importance, role in the design process, benefits, industries that leverage it, available tools and software, challenges, future trends, and more.

What is 3D Modeling?

Before we delve into the significance of 3D Modeling in product design, let’s briefly define what it entails.

3D Modeling is the creation of three-dimensional digital representations of objects using specialized software.

These models can be manipulated, analyzed, and visualized from different angles, providing a realistic preview of the final product.

Importance of Product Design

Product design is crucial as it shapes a product’s user experience, functionality, and aesthetics.

A well-designed product has the potential to attract customers, differentiate itself from competitors, and drive brand loyalty.

Effective product design considers factors such as ergonomics, manufacturability, and cost efficiency, resulting in products that are not only visually adorable but also functional and profitable.

Role of 3D Modeling in Product Design

Enhancing Visualization

One of the primary reasons 3D Modeling is used in product design is its ability to enhance visualization.

Traditional two-dimensional drawings or sketches sometimes need to be revised to convey the complete picture of a product.

With 3D Modeling, designers can create realistic virtual prototypes, allowing stakeholders to visualize the product’s appearance, proportions, and overall design more accurately.

Efficient Iteration Process

Product design is an iterative process that entails many rounds of refinement and enhancement.

3D Modeling streamlines this process by allowing designers to make changes and evaluate different design variations quickly.

Through virtual simulations, designers can test the product’s functionality, ergonomics, and aesthetics, facilitating informed decision-making and reducing the need for physical prototypes.

Simulating Real-World Conditions

3D modeling tools allow designers to simulate real-world conditions and analyze the product’s performance under different scenarios.

For example, engineers can evaluate the structural integrity of a design by subjecting the 3D model to virtual stress tests.

This capability helps identify design flaws, optimize performance, and confirm that the final product meets quality and safety standards.

Collaboration and Communication

Effective collaboration and communication are essential for successful product design.

3D Modeling facilitates collaboration among multidisciplinary teams by providing a shared visual platform.

Designers, engineers, marketers, and other stakeholders can easily view and provide feedback on the 3D model, improving communication, minimizing errors, and aligning everyone’s vision for the product.

Benefits of 3D Modeling in Product Design

Cost and Time Savings

By leveraging 3D Modeling, companies can significantly reduce costs and save periods throughout the product development cycle.

The ability to iterate quickly, identify design flaws early, and optimize production processes helps minimize expensive rework and tooling changes.

Virtual simulations enable companies to validate design choices before investing in physical prototypes, reducing costs.

Improved Design Accuracy

With 3D Modeling, designers can achieve higher design accuracy and precision.

They can meticulously define dimensions, tolerances, and assembly requirements, ensuring the final product meets the desired specifications.

This level of accuracy reduces manufacturing errors and enhances product quality, ultimately leading to customer satisfaction and brand reputation.

Market Testing and Analysis

3D Modeling allows companies to conduct market testing and analysis more effectively.

By creating virtual prototypes, they can gather feedback from potential customers, identify preferences, and make data-driven design decisions.

This iterative process helps align the product with market demands, leading to higher acceptance and market success.

Customization and Personalization

In today’s consumer-centric world, customization and personalization are highly valued.

3D Modeling empowers designers to create customizable products that cater to individual preferences and needs.

By configuring the 3D model parameters, customers can visualize and select personalized options, resulting in unique products that resonate with their tastes.

Industries using 3D Modeling in Product Design

Automotive Industry

The automotive industry heavily relies on 3D Modeling for designing vehicles, components, and interiors.

3D Modeling enables precise visualization of complex designs, aerodynamics analysis, and crash simulations, leading to safer and more fuel-efficient vehicles.

Architecture and Construction

Architects and construction professionals use 3D Modeling to create detailed representations of buildings, bridges, and infrastructure.

3D models aid in visualizing spatial relationships, conducting structural analyses, and presenting design concepts to clients.

Consumer Electronics

The consumer electronics industry benefits from 3D Modeling for designing smartphones, tablets, wearables, and other electronic devices.

It helps optimize the form factor, ergonomics, and internal component layout, resulting in sleek and functional products.

Healthcare and Medical Devices

In healthcare, 3D Modeling is used for designing medical devices, prosthetics, and implants.

It allows for precise anatomical Modeling, customization for patient-specific needs, and simulation of surgical procedures.

Fashion and Jewelry

3D Modeling finds applications in the fashion and jewelry industries as well.

Designers leverage 3D modeling software to create intricate and detailed jewelry designs, visualize how they look on different body types and produce realistic renderings for marketing.

Tools and Software for 3D Modeling in Product Design

CAD Software

Computer-Aided Design (CAD) software forms the foundation of 3D Modeling in product design.

Popular CAD software such as AutoCAD, SolidWorks, and Fusion 360 provide powerful tools for creating, editing and analyzing 3D models.

3D Rendering Software

To create realistic visualizations of 3D models, designers use 3D rendering software like Blender, KeyShot, or V-Ray.

These tools help add textures, lighting effects, and reflections, making the virtual prototypes look almost indistinguishable from actual products.

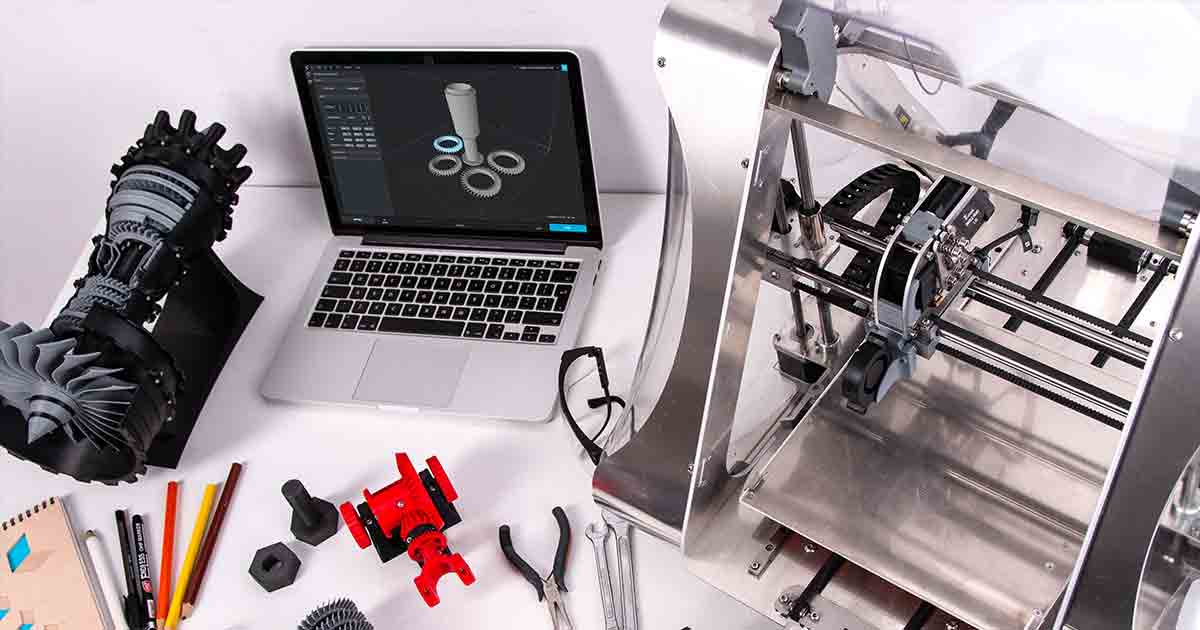

3D Printing and Prototyping Tools

With the rise of additive manufacturing technologies like 3D printing, designers can bring their 3D models to life.

Tools such as slicers, 3D printers, and post-processing equipment enable the creation of physical prototypes directly from digital models, accelerating the product development cycle.

Challenges and Limitations of 3D Modeling in Product Design

Technical Complexity

Mastering 3D modeling techniques and software can be challenging, requiring a learning curve and continuous skill development.

The complexity of advanced features and tools may pose a barrier for some designers, causing training and practice to harness the full potential of 3D Modeling.

Expensive Equipment and Software

Acquiring the necessary hardware and software for 3D Modeling can be a significant investment, especially for small businesses or individual designers.

High-performance computers, powerful graphics cards, and licensed software may incur substantial costs, impacting the accessibility of 3D modeling technology.

Skill and Training Requirements

3D modeling proficiency requires technical skills, artistic creativity, and design understanding.

Designers need to develop expertise in CAD software, understand engineering principles, and stay updated with emerging trends and techniques.

Continuous learning and training are crucial to remain competitive in the field.

Intellectual Property Concerns

The digital nature of 3D models raises concerns about intellectual property (IP) protection.

Designers need to safeguard their designs from unauthorized use or replication.

Watermarking, encryption, and legal measures help protect the ownership rights of 3D models.

Future Trends in 3D Modeling for Product Design

Integration with AI and Machine Learning

Integrating 3D Modeling with artificial intelligence (AI) and machine learning (ML) algorithms holds immense potential.

AI-powered design assistants, automated generative design algorithms, and ML-driven optimization can augment designers’ capabilities, leading to more efficient and innovative product designs.

Virtual Reality (VR) and Augmented Reality (AR)

Virtual and augmented reality technologies are transforming how designers interact with 3D models.

VR allows designers to immerse themselves in a virtual environment and experience product design at a human scale.

AR enables designers to overlay virtual models onto the real world, facilitating design reviews and visualizations in real-world contexts.

Generative Design and Parametric Modeling

Generative design techniques, coupled with 3D Modeling, enable the creation of innovative designs based on specified constraints and performance requirements.

Parametric Modeling empowers designers to create flexible designs that can be easily changed by adjusting parameters, enhancing design flexibility and customization.

Sustainable Design and Materials

As sustainability becomes increasingly essential, 3D Modeling can contribute to eco-friendly product design.

By simulating material properties, analyzing energy consumption, and optimizing resource usage, designers can develop more sustainable products that minimize environmental impact.

Conclusion

3D Modeling has revolutionized the field of product design by offering powerful tools for visualization, iteration, and simulation.

It enhances the design process, enables efficient collaboration, and provides many benefits, such as cost savings, improved accuracy, and market testing.

Industries from automotive to fashion leverage 3D Modeling to create innovative and successful products.

Despite challenges and limitations, the future of 3D Modeling in product design looks promising, with integration with AI, VR/AR, and sustainable design leading the way.

FAQs (Frequently Asked Questions)

Q 1: How does 3D modeling benefit product designers?

3D modeling benefits product designers by enhancing visualization, streamlining the iteration process, simulating real-world conditions, and facilitating stakeholder collaboration and communication.

It improves design accuracy, reduces costs and time, and enables market testing and analysis.

Q 2: Can 3D Modeling be used for complex product designs?

Yes, 3D Modeling is highly suitable for complex product designs.

It allows designers to create detailed virtual prototypes, analyze intricate geometries, and simulate complex interactions, ensuring that the outcome meets the required specifications.

Q 3: What industries benefit the most from 3D Modeling in product design?

Several industries benefit from 3D Modeling in product design.

The automotive industry, architecture and construction, consumer electronics, healthcare and medical devices, and fashion and jewelry are among the sectors that extensively leverage 3D Modeling for designing innovative products.

Q 4: What are some popular 3D modeling software options for product design?

Popular 3D modeling software options for product design include AutoCAD, SolidWorks, Fusion 360, Blender, KeyShot, and V-Ray.

These software packages offer powerful tools and features for creating, editing, and visualizing 3D models.

Q 5: How does 3D Modeling contribute to the future of product design?

The future of product design will witness further integration of 3D Modeling with AI and machine learning, enabling automated design help and optimization.

Virtual reality and augmented reality will enhance the immersive design experience.

Generative design, parametric Modeling, and sustainable design practices will also shape the future of product design, leading to more innovative, customizable, and eco-friendly products.